Like many of its contemporaries the Colonial 2 apartment building was an uninsulated energy guzzler. Prior to the energy crisis in 1973, most buildings in the US were constructed with little or no insulation.

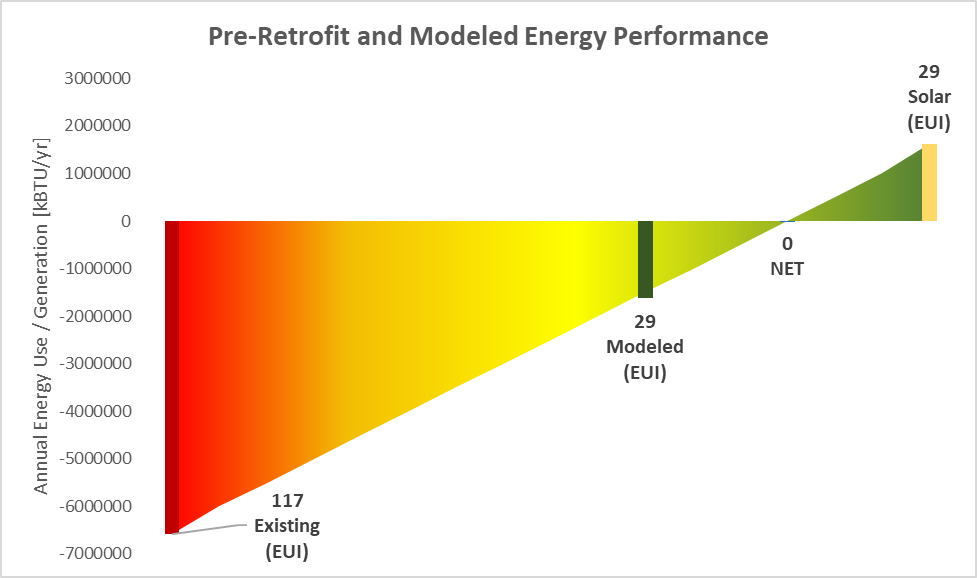

Still in service today, many of these buildings are huge energy consumers that provide poor comfort to their occupants. With no insulation in the walls and very little on the roof it is unsurprising that the EUI for Colonial 2 averaged 117[kBTU/sqft yr] in the years before its renovation. The ubiquity of this building type underlines the importance of energy retrofit strategies for these buildings.

Beacon Communities hired RIDA Architecture and Staengl Engineering to design a deep energy retrofit project for Colonial 2. The design won a grant under the NYSERDA buildings of excellence program to help fund the work. The critical first step in any deep energy retrofit is to insulate and tighten up the building envelope. For this project it was possible to apply an improved air barrier, additional insulation on the exterior, and new high-performance windows. These envelope improvements will greatly reduce heating energy use, improve comfort, and make it feasible to provide required heat with smaller heat pump equipment. The original building was heated by two, 2.6 Million BTU/hr gas fired boilers. Domestic hot water was heated by two 300,000 BTU/hr gas fired hot water heaters.

The replacement HVAC system is based on “all-in-one” vertical ground source heat pumps. Geothermal heat pumps are used because of the cold climate in Rome NY (climate zone 6), with outdoor extremes down to -27 F. The selected heat pumps have integrated ERVs and are configured in a simple stacked configuration that allows easy distribution of loop water and heat pump power. The all-in-one configuration allowed for ease of installation and reduced on-site labor and disturbance of the occupants. The only ductwork required was the bathroom exhaust (back to the unit), the kitchen exhaust duct, and the OSA intake and exhaust ductwork from the heat pump’s ERV. The installed total heat pump capacity came to just under 1 million BTU/hr, which is about 20% of the originally installed boiler capacity!

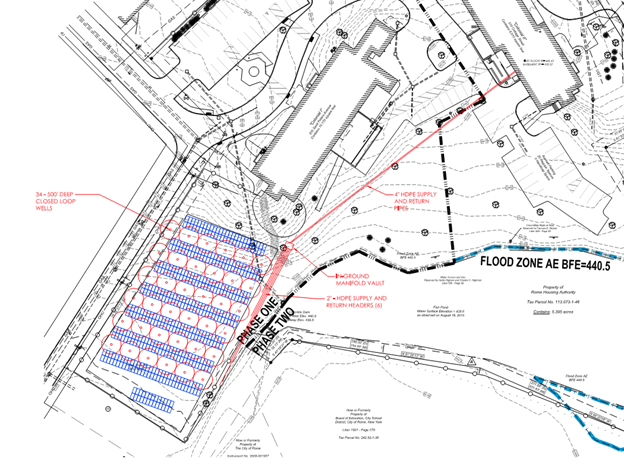

The geothermal well field that serves the building is installed in an adjacent field. The solar field is installed above the geothermal loop field. The solar field is designed to produce all the required electricity for the building on a net annual basis.

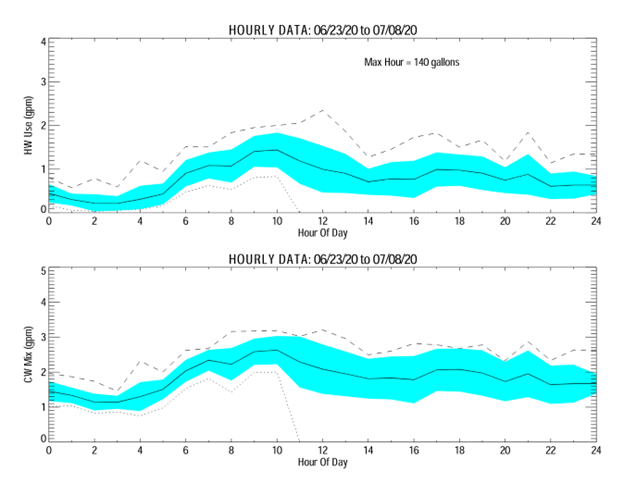

Domestic hot water for the building is heated by heat pumps with carbon dioxide as the refrigerant. To size the hot water system correctly, water consumption in the building was measured prior to the retrofit. Hot water consumption peaks for this population were found to be relatively low. This allowed us to confidently size the heat pump system serving the building, and to right-size the domestic hot water piping system. Thanks to Earth Environmental Group for assistance with hot water measurement.

The insulation and equipment measures implemented in the deep energy retrofit are expected to reduce the building energy consumption by more than 75%. The remaining 25% will be taken care of by the on-site solar field. It is gratifying to turn this old energy hog into a net-zero energy building! Energy analysis courtesy of L&S Energy Services.

Founder Mechanical Engineer

Sign up for the latest information in engineering building science.

STAENGL ENGINEERING

Copyright 2024 all rights reserved

Privacy Policy I Terms of Service I Website Design by Dwelling Creative