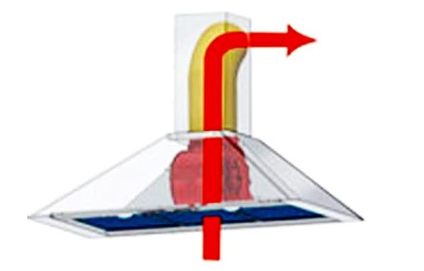

Passive House standards require that each building envelope be thoroughly sealed for maximum energy efficiency and control of ventilation. To provide proper ventilation, passive house builders typically use MVHR or ERV systems to bring in continuous fresh air and exhaust the kitchens and bathrooms at a constant but slow rate. With this, recirculating range hoods, which filter and recirculate the air that’s already in the kitchen but don’t vent the air to the outside, have historically been a standard solution for Passive House projects.

So how do Passive House builders simultaneously maintain a maximally-sealed building envelope and high indoor air quality for their residents? If you exhaust 150-200 CFM from a range hood, you’ll need to find a way to keep the building’s air pressure balanced by bringing the same amount of air into the building. This is a challenge for single-family residences, but an especially tall order for apartment buildings with 50-100 units.

The Passive House Institute US (Phius) has specifically looked into this question. In their research, the Technical Committee has found that only 11-13% of range hoods in a building of this size will operate simultaneously, even during peak cooking hours. In some instances, a maximum exhaust rate increase of 13% may not even require additional makeup air to offset it, especially because ducted range hoods’ intermittent ventilation already reduces the need for continuous low-rate kitchen exhaust and ventilation. This decreased demand for continuous airflow also makes the building more energy-efficient.

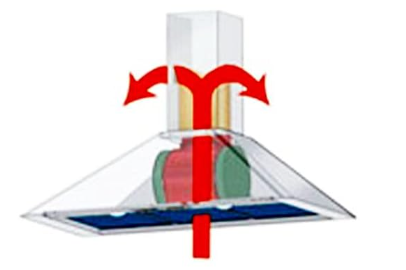

The other challenge with installing ducted ranges is the large holes that the ducted range hoods demand. Without the proper seals or gaskets, these openings can be significant enough to create a major source of leakage. Various backdraft dampers can either be installed at the outside of the building or even inside the ductwork to try accounting for this problem, but pressurization and depressurization tests have found that many backdraft dampers don’t have proper sealing and still allow for significant inflow leakage.

Ducted range hoods with gasketed, well-sealing backdraft dampers, on the other hand, perform well in depressurization tests. They manage to prevent almost all inflow leakage, assuming the ducts themselves are also properly sealed to the exterior facade. This solution means the building can strike the delicate balance between air-tightness and healthy indoor air quality. In taller buildings it may be necessary to install automatic dampers in the kitchen exhaust duct, that will be open during operation, and shut tight when there is no cooking occurring.

Founder Mechanical Engineer

Sign up for the latest information in engineering building science.

STAENGL ENGINEERING

Copyright 2024 all rights reserved

Privacy Policy I Terms of Service I Website Design by Dwelling Creative